A Kiln is a Potter's Partner

Gas kilns I built, inherited and bought.

"Temperature means nothing unless time goes with it."

--Jim Bailey, kiln builder

|

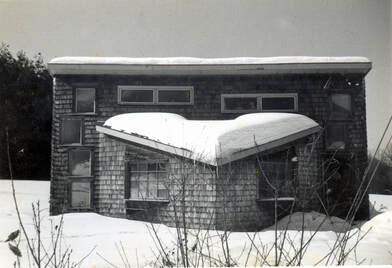

Kiln # 1 in service 1971 to 1974

First studio designed by architect Mervyn Fernandez. Kiln is inside the building; owner-built (thanks to coaching from Phil Homes). LP Gas Kiln: downdraught, top-loaded insulating firebrick indoor kiln. Roof made of insulating firebrick suspended on stainless steel rods. 44˚16'15.15" North, 72˚25'3.09" West Cameron Road, Plainfield, Vermont. |

|

Kiln #3 in service 1979 to 1981 Industrially built in 1947, an updraught muffle kiln lined with ceramic tubes that protected ware from flame impingement. It was made for natural gas and converted to LP gas. A gift from Rita Price (it had been Job Negiem's kiln). 41˚31'13.19"North 70˚40'7.04"West Juniper Point, Woods Hole MA |

|

Kiln #4 in service 1979 to 1997 This downdraft sprung-arch LP gas-fired kiln had four burners and an exit flue in the middle of the floor that tunneled under the floor. Eleven inch thick wall construction was a sandwich of super-duty hard brick interior, insulating firebrick on edge, hard-brick exterior. Arch brick interior was covered with castable refractory insulation and poured vermiculite. Owner-designed and built with foundation by Tom Renshaw, steel design and welding by Peter Bumpus. 41˚31'13.19"North 70˚40'7.04"West Juniper Point, Woods Hole MA |

|

Kiln #4 Having built this, seeing it come apart was indescribably fascinating. I read bricks as people read books and both have stories to tell. These bricks went to a young man who expected to fire pots and make pizza and bread. Known history of these bricks: Brooklyn Navy Yard donated to Goddard College, some to me. Other bricks, from a later time, from two sites at Otis Air Force Base. |

|

Kiln # 5 in service 1997 to 2016 A downdraught shuttle kiln that was fired with natural gas. It had two burners and two blowers. It's the kiln I bought for developing work using marine materials as glazes. It was designed and built by Bailey Ceramics. 41˚29'50"North, 70˚39'.42"West Juniper Point, Woods Hole MA As of October 2016, Zanatali was disassembled: bricks, venting and burners went to New York, steel was been scrapped. |